In today’s industrial landscape, ensuring the safety of workers is paramount. Among various safety concerns, fall protection stands out due to its critical importance in preventing injuries and fatalities. As industries evolve, so do the strategies and equipment designed to protect workers from fall-related hazards. This article delves deep into the concept of fall protection, exploring its significance, regulatory frameworks, types, and best practices.

The Importance of Fall Protection

Falls from heights are a leading cause of workplace injuries and fatalities. According to the Occupational Safety and Health Administration (OSHA), falls account for a significant percentage of all occupational deaths. Implementing effective fall protection measures not only safeguards employees but also enhances productivity and morale, reduces downtime, and minimizes potential legal liabilities for organizations.

Regulatory Frameworks Governing Fall Protection

Several regulatory bodies have established standards to ensure workplace safety concerning fall hazards:

- Occupational Safety and Health Administration (OSHA): In the United States, OSHA sets forth regulations requiring employers to provide fall protection systems for workers at specific height thresholds. These standards encompass various industries, including construction, general industry, maritime, and agriculture. Employers are mandated to implement measures such as guardrails, safety nets, or personal fall arrest systems to protect workers from fall hazards.

- American National Standards Institute (ANSI): ANSI provides guidelines, such as the ANSI Z359 series, detailing fall protection equipment and system requirements. These standards serve as benchmarks for designing, testing, and implementing fall protection systems, ensuring they meet stringent safety criteria.

Types of Fall Protection Systems

Understanding the different categories of fall protection is crucial for selecting and implementing the appropriate measures:

- Fall Elimination: The most effective form of fall protection involves modifying the work environment or procedures to eliminate the need to work at heights. This can include using tools with extended handles or performing tasks at ground level.

- Fall Prevention: These systems aim to prevent workers from reaching fall hazards. Examples include guardrails, barriers, and hole covers that physically block access to edges or openings.

- Fall Restraint: This approach uses equipment to restrict a worker’s movement, preventing them from reaching areas where falls could occur. Restraint systems typically involve body belts or harnesses connected to anchor points, limiting the worker’s range of motion.

- fall arrest: When a fall occurs, fall arrest systems are designed to stop the fall safely. Personal fall arrest systems (PFAS) include components such as full-body harnesses, lanyards, and anchorages that work together to arrest a fall and minimize injury.

- Administrative Controls: These involve implementing work practices or procedures to mitigate fall hazards, such as training programs, warning signs, and designated safe zones.

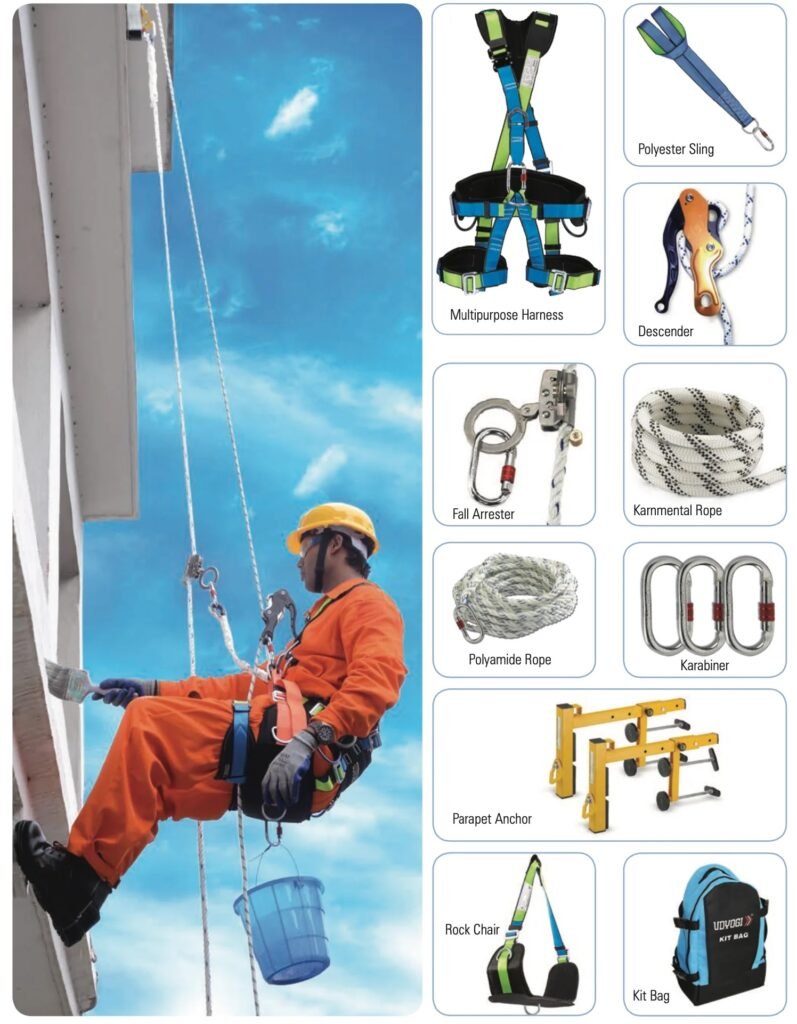

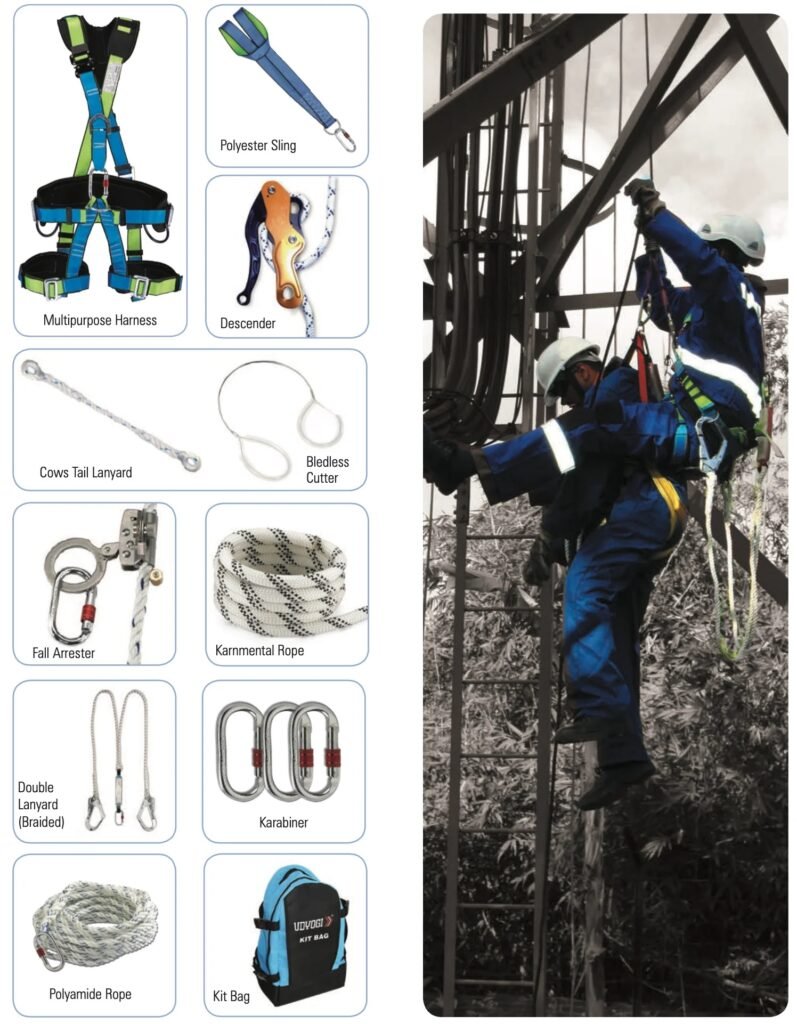

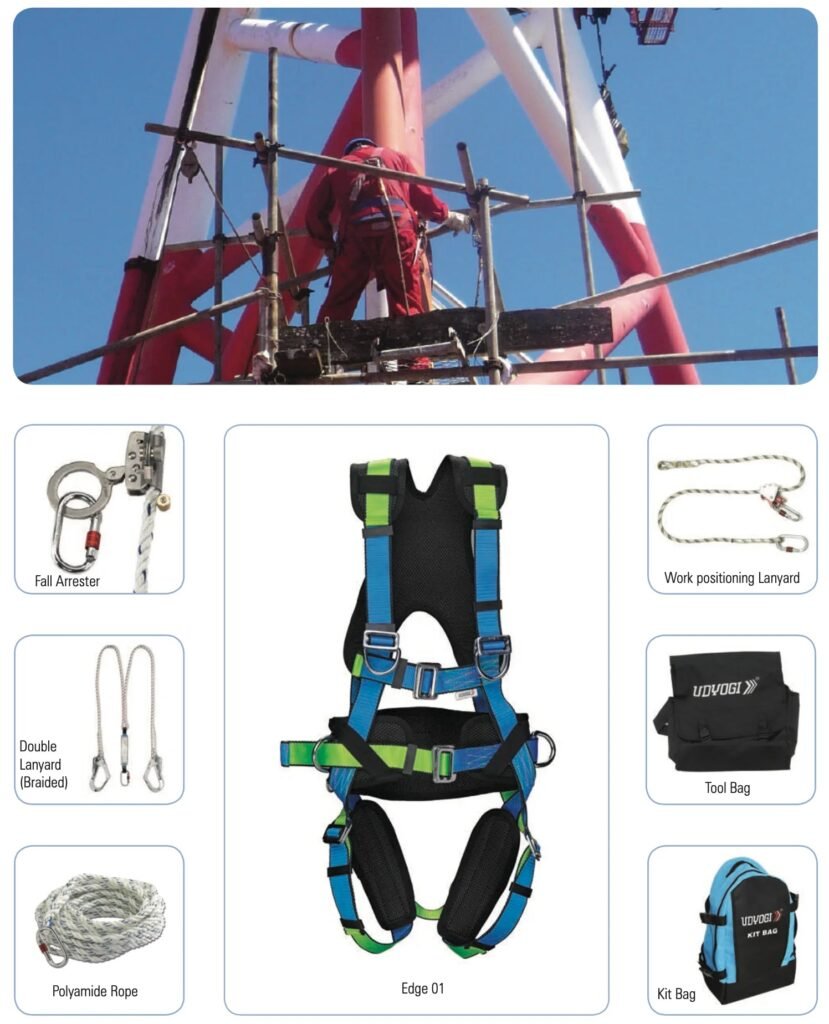

Components of Personal Fall Arrest Systems (PFAS)

A comprehensive PFAS consists of five essential elements, often referred to as the ABCDEs of fall arrest:

- A – Anchorage: A secure point of attachment for lifelines, lanyards, or deceleration devices. Anchorages must be capable of supporting specific loads to ensure they can withstand the forces generated during a fall.

- B – Body Wear: Full-body harnesses distribute fall arrest forces across the shoulders, thighs, and pelvis, reducing the risk of injury. They are designed to keep the worker upright during and after a fall.

- C – Connector: Devices such as lanyards or lifelines that link the harness to the anchorage point. Connectors may include shock-absorbing features to reduce the impact forces during a fall.

- D – Deceleration Device: Mechanisms like shock absorbers or self-retracting lifelines that dissipate the energy of a fall, controlling the deceleration and minimizing forces on the worker.

- E – Emergency Plan & Equipment: Preparedness for rescuing a worker after a fall is crucial. This includes having a clear rescue plan, trained personnel, and appropriate equipment to retrieve a fallen worker promptly.

Best Practices for Implementing Fall Protection

To effectively protect workers from fall hazards, organizations should adopt the following best practices:

- Conduct Thorough Risk Assessments: Identify all potential fall hazards in the workplace by evaluating tasks, equipment, and environments. Regular assessments help in recognizing new hazards as work conditions change.

- Develop and Enforce a Fall Protection Plan: Create a comprehensive plan that outlines procedures for identifying hazards, selecting appropriate fall protection systems, and responding to fall incidents. Ensure the plan complies with regulatory standards and is tailored to the specific work environment.

- Provide Comprehensive Training: Educate workers on the proper use, maintenance, and inspection of fall protection equipment. Training should also cover recognizing fall hazards and understanding the organization’s fall protection plan.

- Regularly Inspect and Maintain Equipment: Implement routine inspection protocols to ensure all fall protection equipment remains in optimal condition. Replace any damaged or worn components promptly to maintain system integrity.

- Foster a Safety Culture: Encourage open communication about safety concerns and involve workers in safety planning. A strong safety culture promotes vigilance and proactive behavior in identifying and addressing fall hazards.

Challenges and Considerations in Fall Protection

While implementing fall protection measures is essential, organizations may encounter challenges such as:

- Complex Work Environments: Irregular structures or confined spaces can make standard fall protection systems difficult to apply. Customized solutions may be necessary to address unique hazards.

- Worker Compliance: Ensuring that all employees consistently use fall protection equipment correctly requires ongoing training, supervision, and reinforcement of safety protocols.

- Equipment Compatibility: Mixing components from different manufacturers can lead to compatibility issues, potentially compromising the effectiveness of the fall protection system. It’s crucial to use equipment that is designed to work together.

Emerging Trends in Fall Protection

The field of fall protection continues to evolve with advancements aimed at enhancing worker safety:

- Innovative Equipment Designs: Manufacturers are developing lighter, more comfortable harnesses and connectors to improve worker compliance and reduce fatigue.

- Technological Integration: The incorporation of technology, such as sensors and IoT devices, allows for real-time monitoring of worker movements and environmental conditions, enabling proactive hazard identification and response.

- Enhanced Training Programs: Virtual reality (VR) and augmented reality (AR) are being utilized to provide immersive training experiences, allowing workers to practice fall protection procedures in a controlled, simulated environment.